Subcategory

Thematic articles

Projects

-

Ecological heating

-

Ecological conveyor belt

-

Nanopaint

-

Algae producing nanogold

-

Helper in Hydrology – Floreon+

-

Nanobrakes

-

Biomass as an alternative in the energy system

-

Nanoparticles in the role of an environmentalist

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Ecological heating

When burning solid fuels in small furnaces, the creation of pollutants always occurs. There are roughly four basic parameters that fundamentally affect the amount and character of these pollutants. This refers to depending to the type of combustion device, type of fuel, quality of operation and maintenance and the actual installation of the heating equipment itself. In other words, it is important what we heat in, what we heat with, where and how we heat and how the heater is maintained. Each of these factors significantly affects the quality of the combustion process, the efficiency of the combustion device and thus the consumption of fuel. If one of these parameters is deficient, then the overall result is bad. It is thus not enough to merely replace an old furnace with a new one and think that everything will be fine.

When heating with solid fuels, households produce approximately one-third of all dust released into the atmosphere in the Czech Republic. In order to improve this situation, the university team is working mainly on the development of new combustion devices as well as on the modernisation of old ones. They are monitoring the parameters of utilised fuels and examining the possibility of producing new types, such as mixed briquettes, pellets, etc.

The resulting emissions of harmful materials from furnaces are very dissimilar because product badges state ideal values that are often unachievable in real-world operation. They therefore pose the question: What does this have in common with heating in everyday life? They are thus wagering not on the parameters achieved during certification, but rather on the common sense of users. They created the SMOKEMAN character, who does not like smoke and shows the general public how to heat correctly and how to simply measure and, mainly, to improve the efficiency of furnaces. Much thus depends on us – a furnace is only a machine.

The educational show “Smokeman Intervenes” is intended for both young and old audiences. Children learn through comic books, board games and colouring books, while older people can experience at first hand how low-quality fuel and waste significantly influence the production of smoke.

They believe that patiently conveyed information will eventually result in beneficial habits of users. They hope that burning waste in a furnace will become taboo for the younger generation just as drying firewood is an absolute matter of course.

Energy Research Centre, VŠB – Technical University of Ostrava

http://vec.vsb.cz/smokeman

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/technicke-vychytavky/ekologicky-pasovy-dopravnik/

Ecological conveyor belt

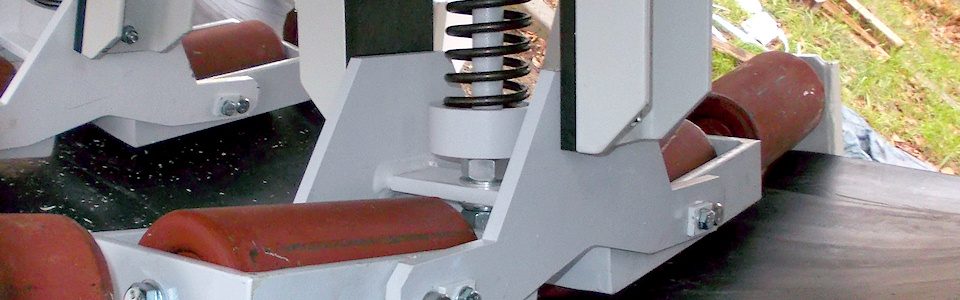

The conventional belt conveyors are reliable helpers in surface mines, thermal power plants, in the food industry, post offices, airports, but also in construction and reconstruction of buildings. They mostly transport material horizontally or with a slope of up to 18 degrees. The conveyor belt is made of rubber or plastic and the transported gravel, sand, grain or coal is easily held on it due to friction. Transport in larger inclinations is possible, but to overcome the force of gravity, it is necessary to modify the surface of the conveyor belt, for example by vulcanizing projections, grooving or retrofitting transverse ribs. This solution is not entirely complete and conceptual because the divided belt can hold less material. And there is still the problem of high dustiness during transportation…

The university team came up with the idea how to solve the problem. What about simply pushing the conveyed material to the conveyor belt? Imagine two horizontal conveyor belts one above the other, the bottom one is flat and the upper one has a shape of a convex trough. Each one moves independently of the other and the transported material is literally squeezed between them. It must be added that the design is not as simple as it might seem and requires many years of work and looking for the optimal solution. They have furnished the upper belt with pressure rollers to ensure the pressure of the material while preventing the raw material during transport from falling over the edges of the belt. This technology has many advantages. It is undemanding with respect to space, the conveyor belt can transport material from the ground floor to the upper floors, literally in the perpendicular direction. The conveyor transports more material at the same time, while the material is protected from the weather. Belts without transverse ribs are easier to clean, they are utilized more economically and they produce less dust, which has a positive impact on the environment. There are many good reasons why the technology of a double belt conveyor and roller mills was patented and why it is also protected by a utility model.

This device was developed by the team lead by Leopold Hrabovský from the Faculty of Mechanical Engineering, VŠB-TUO in cooperation with the company SE-MI TECHNOLOGY, a.s. within the project TAČR (Technology Agency of the Czech Republic) Alfa

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Nanopaint

Have you heard about coating materials that are durable, abrasion-resistant, waterproof and harmless? These are terms that you read on almost every can of paint. But have you also heard about paint that can effectively eliminate harmful substances and bacteria? No? Allow us to tell you about it.

The university team has developed special powdered materials that have a range of fineness comparable to that of flour to coarse-grain kitchen salt. Their prime ingredient is a clay material, most commonly kaolinite, which is a readily available material used for making ceramics. Particles of these clays have the shape of discs, which you can imagine as metal coins, and nanoparticles of the secondary ingredient – metal oxides such as TiO2 or ZnO – are bound to their surface. When the surface of these composites is exposed to light, very reactive particles are created which function as traps for harmful substances and bacteria in the air and water. This is very beneficial for both the construction industry as well as for the environment.

They mix these powdered materials into paint, whose properties they can thus change literally at the molecular level. Thanks to the reactive capabilities of the nanoparticles, such coating materials have the parameters of the highest-quality paint and are finding ever broader applications.

Uses for nanocomposites can be found in numerous industrial sectors, for example in the construction industry as an additive in self-cleaning construction and coating materials, as an additive in plastics and as a medium for cleaning wastewater and gases. A typical example is usage in hospitals and other healthcare facilities, where strict rules for cleanliness and hygiene are in force. The nanoworld offers seemingly invisible improvements, but with enormous potential to enrich our “big” world.

Nanotechnology Centre, VŠB – Technical University of Ostrava

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/technicke-vychytavky/rasy-vyrabejici-nanozlato/

Algae producing nanogold

In addition to producing jewellery, gold is widely used in industry, technology, as a material for making electrical computer components, joint replacements in medicine, chemists work with it. Research showed that nanogold has excellent catalytic properties (much like platinum or palladium), and can accelerate or retard chemical reactions. Particles that have at least one dimension in the nanometer range have a larger reactive area and their catalytic properties will increase. Apart from the purely chemical methods for preparing nanoparticles, there is one more chemical-biological way, and we got that route.

In the university Bionanotechnology Laboratory, they use algae with siliceous structures to prepare nanogold. Diatoms and golden algae (chrysomonades) have unique features, they represent the largest biomass on Earth and, in addition to that, they can move. If these algae are mixed with highly diluted acid solution of tetrachlorogold acid, after a short time, gold nanoparticles are eliminated, they are stabilized and become part of cellular slime on siliceous algae structures. The elimination (reducing) of gold from the solution takes place due to the effect of various biomolecules that living cells produce when preventing the toxic effect of metal cations.

The resulting gold nanoparticles may have a variety of uses, for example in the catalytic decomposition of carbon monoxide. They accelerate the decomposition of hazardous substances such as nerve poison soman and VX agent. In the future, they are considering the disposal of pollutants in contaminated soil, water, air, clothes using nanoparticles of gold or silver. For these purposes, other biomass – for example plant – may be used, as its acquisition is not as complicated as in the case of microorganisms; it can also represent a new use for bioorganic or waste material.

Ladies would probably prefer wearing gold on their neck rather that seeing it in the laboratory, but can assure them that during one month, they prepare 1.5 g of silica boxes with organic residues with purple (!) gold nanoparticles invisible to naked eye. Although it is not enough to produce jewellery, science can achieve great things even with such a small amount of rare metal.

Nanotechnology Centre of VŠB – Technical University of Ostrava in cooperation with the State Institute for Nuclear, Chemical and Biological Defence.

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Helper in Hydrology – Floreon+

Can you remember some of the action film villains who wanted to destroy the world with their super computers? There have been lots of them! The university Floreon+ system is one of its kind and, conversely, can save the part of the world where we live.

The objective of the Floreon+ is to model, predict and support the resolution of crisis situations, with particular focus on the Moravian-Silesian region. This system, which is being developed within a research and development project, allows for easy integration of various topic-specific areas, regions and data thanks to its flexibility and openness.

Floreon+ is currently being used, for example, by the Integrated Security Centre of the Moravian-Silesian Region where it monitors the behaviour of the main water streams in the MS Region in real time and is able, for example, to detect an impending flood. It simulates and predicts its course and minimises its impact by suggesting a timely measure. Such a measure can be the timely evacuation of population from the critical areas, the construction of an anti-flood barrier or a plan for securing transport accessibility of the affected areas.

In addition to that, the Floreon+ system can also be used to predict air pollution and pollution of water streams in the event of leaks of dangerous substances, which occur, for example, during environmental accidents. However, all these simulations are so calculation-intensive and data-intensive that it is not within the capacity of a person or a standard computer to perform these tasks in the necessary timeframe. This is why the Floreon+ system is installed on super computers, which repeatedly perform these tasks with machine precision and tirelessness in seconds or minutes and, moreover, in many variants that can occur in reality.

A similar system was missing, for example, during the tsunami in Indian Ocean in 2004. We have it now. To the maximum possible extent, it helps to create a safe environment for the population in the area it covers. And it also provides certainty that a citizen will be warned and will be saved, along with their possessions, in a timely manner during extraordinary events.

National super computer centre IT4Innovations at VŠB – Technical University of Ostrava

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Nanobrakes

Have you ever considered what happens between the brake rotor and pads when you step on the brake pedal in your car? Technically, it is completely obvious. With each press of the brake pedal, the hydraulic calliper presses the brake pads to the rotor and the car slows down. But doesn’t something else happen that isn’t visible at first glance? Yes, it does. In each instance of braking a certain number of very fine particles are ground off of the brake pads. These particles are thus released into the surrounding environment and some of them end up in the soil.

The University laboratory is one of the first in Europe to discover that the abraded material from brake pads is so small and light (a million times smaller than a millimetre) that they remain in the air due to the negligible gravitational effect on them. Such small particles present a risk not only for the environment, but also for the health of living organisms, including humans, because they penetrate tissue when inhaled. When we take into consideration that there are approximately 250,000,000 cars in operation in Europe alone, it occurs to us how serious this problem is.

The objective of the university project is testing, characterisation and development of new materials for brake pads used in passenger cars. As we now know how hazardous the currently used brake-pad materials are, they are striving to figure out how to produce brake pads so that they do not contain lead and other hazardous substances. Using advanced computer simulations and measuring technology, tehy are developing revolutionary, new-generation materials that will not have any negative health or environmental impacts as they are subjected to wear and tear. As a point of interest, we can state that they are working crushed nutshells and other alternative materials into the mix.

Successful development of these brake “nanoparticles” and introduction thereof into practice will mean that drivers can brake more effectively. And all of us will breathe easier.

Nanotechnology Centre, VŠB – Technical University of Ostrava in cooperation with specialists from the United States and China.

www.cnt.vsb.cz

Biomass as an alternative in the energy system

As part of its efforts to reduce energy consumption and CO2 emissions, Ostrava’s zoo has built a boiler system burning biomass (woodchips) as part of its dendrology complex. The zoo covers a large area, and is a permanent source of wood-based biomass. The zoo uses a chipper, loader and tractor to harvest and process the biomass before burning.

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Nanoparticles in the role of an environmentalist

They are a million times smaller than a millimeter, but if they spread, they can cover a huge area. We are talking about nanoparticles, super tiny crystals, whose world we gradually uncover thanks to the latest technology. Specific properties of nanoparticles can, for example, be also utilized for the protection of the environment. Imagine a catalyst of exhaust gases from automobiles. A thin layer of a special powder is applied round its inner circumference. The resulting coating can destroy harmful substances produced by the combustion of petrol. In fact, when striking this surface, these substances are deformed and decomposed into simple gases – hydrogen and nitrogen. But even nanoparticles do not work as a perpetual motion machine, they need a supply of energy for their activity. For example, light. Thanks to it, they become more active “trap for pollutants” and they also decompose them significantly faster.

In university research, they focus on the preparation of so called semiconductor nanoparticles (e.g. titanium dioxide, zinc oxide), which can, with the help of sunlight, decompose toxic and poorly biodegradable substances. They are working on the problem of artificial production of hydrogen, inducing artificial photosynthesis and on new technologies of preparation of powders of nanoparticles. These are the instructions for producing the original mixtures of different metal salts and lye; they have already discovered twenty of them. All with a single goal. Helping man to protect the world in which we live. The nanoparticles treated in this way can, for example, convert greenhouse gases into harmless substances which find further application in the industry. They help us remove impurities from oil spills out of water. As coatings in hospital wards, they prevent the formation of mildew and destroy bacteria. They can also be used for the production of filters in chimneys and for wastewater purification. Nanoparticles are becoming an important tool in protecting the environment and improving the quality of life of people.

The research is conducted by the team led by Ladislav Svoboda from the Faculty of Metallurgy and Materials Engineering, VŠB – Technical University of Ostrava

Fact sheets

Factors

Factors influencing air quality in Ostrava include sources of air pollution (industry, transport, local heating sources), the physical geography of the city and the surrounding area, and especially meteorological conditions.

Air quality monitoring stations

Emissions of solid pollutants (TSP)

Reduction in emissions of solid pollutants (total suspended particles – REZZO 1 = industry) in the Ostrava district, 1980-2010. Industrial activity is the most important factor influencing air quality. This represents a major improvement compared to previous years.

Emissions of solid pollutants (TSP)

Reduction in emissions of solid pollutants (total suspended particles – REZZO 1-3 = industry, mid-sized stationary sources, heating sources) in Ostrava, 1994-2010. This again represents a major improvement compared to previous years.

Emissions of solid pollutants (TSP)

Reduction in emissions of solid pollutants (total suspended particles) by the company ArcelorMittal, 1978-2015 – thanks to investments in modernization and environmental improvements at the plant.

PM10 concentration

Reduction in mean annual concentration of PM10 airborne particulates in Ostrava, 2005-2016.

Dust-collecting street-sweeping machines

![]()

The number of dust-collecting street-sweeping vehicles operated by the City of Ostrava’s road management corporation; these machines collect hundreds of tonnes of dust and other debris during the course of the year. Other similar machines are operated by the individual municipal districts that make up the city.

Greenery

Green spaces are the lungs of a city. The sum (in CZK) released by the City from its annual budget and transferred to the individual municipal districts to fund regular maintenance of Ostrava’s parks and green spaces.

Greenery

The number of trees/shrubs planted in 2013-2015 as part of Ostrava’s ‘Green Screens’ projects. The green screens act as filters, helping to shield residential areas from industrial sites or busy roads.