Subcategory

Thematic articles

Projects

-

The energy system of a house

-

Water treatment using magnetic field

-

Energy accumulation

-

deRadon – “Cleaner wells guaranteed”

-

Ecological heating

-

Clean mining technology

-

Energy savings in industry

-

Ecological conveyor belt

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

The energy system of a house

If you are often away from home, you will appreciate the ability to manage a “life” in your house remotely. Yes, nowadays, with the emerging technologies, you can turn on the light in your house, turn on the washing machine, or adjust the heating thousands of kilometers away.

Do so called control system of a house can involve common household appliances, but also various energy sources. All with the aim of optimizing the energy consumption in the building. What about an electric car? It is driven by an electric motor, and a battery is usually used as a power source, it must be charged before driving, and the driving distance of the vehicle depends on its capacity. An electric car may not only serve as an environmentally friendly, elegant and quiet means of transport. If it was included in the system of a house, it could serve as an intelligent mass storage of electricity. Electric vehicles may therefore function not only as means of transport, but they can feed energy back into the network – using intelligent technology of charging and discharging.

Also, the team of scientists and students of the Department of Cybernetics and Biomedical Engineering has long been involved in optimizing the network control system of a house. Although the theoretical and practical results are excellent, generally, greater expansion of electric vehicles faces several challenges. Public awareness about electric cars is associated with misleading information about the high purchase price of the vehicle and the absence of efficient batteries for adequate driving range. More than this, the problem is the still developing infrastructure and insufficient supply of manufacturers of electric vehicles. Even so, it can be assumed that the globalization of the market, growth in fossil fuel prices and stricter environmental protection will enable their future use, not only in transport.

The Faculty of Electrical Engineering and Computer Science, VŠB-TUO

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Water treatment using magnetic field

Any solid particle substance which has magnetic properties can be influenced by a magnetic field. For many years, the university team has been engaged in research in the field of magnetism. Their suggestions and improvements of the magnetic field generator are used in industrial plants that are beneficial to all of us, whether they are magnetic flaw detectors that detect manufacturing and operating defects in steel pipes and cables or new materials for data storage – CD and DVD.

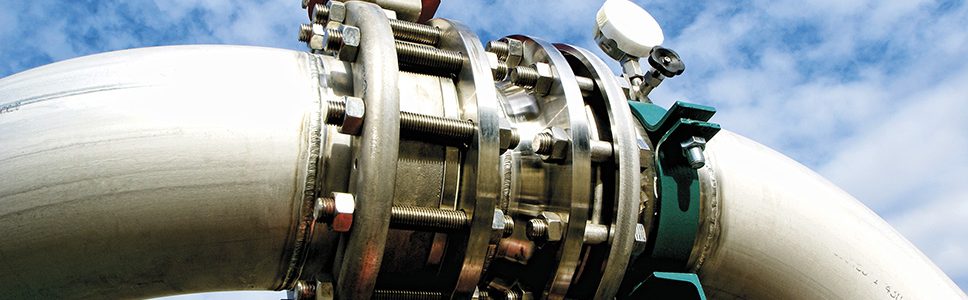

Promising application of their research is the elimination of mechanical parts in drinking water. Depending on the degree of pollution in a given location, it is good to clean water, because we drink it, but also to prevent impurities from clogging kitchen appliances and water pipes themselves. The existing filters located in pipes contained an electromagnet, or they used the phenomenon that each conductor through which the electric current is passing also has the magnetic properties.

The indisputable advantage of their device is an autonomous solution, i.e. it is independent of the electricity distribution network. The base consists of a ring with permanent magnets produced from the rare earths. These types of magnets are characterized by high values of bulk density of magnetic energy. This makes it possible to produce a strong magnetic field in the ring cavity. After attaching the ring to the mechanical water filter, the field will affect the particles entrained in the water piping. Particles (dirt) are gradually deposited on the inside of the mechanical filter. We can simply take it out and remove the dirt by rinsing it under running water, screw it back, and the separation may continue.

Their facility can be used wherever water flows through water pipes. This will be most certainly appreciated by owners of weekend houses and cottages, or users or objects without an electrical connection. Currently, they are in contact with the commercial sector and gather all the necessary documents, results of measurements and analysis of water and impurities trapped to start industrial production.

The Nanotechnology Centre and the Institute of Physics, VŠB-TUO, participate in this research

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Energy accumulation

There is sufficient energy around us, but it may not always be available in a useful state or at the moment when we need it. For example, the sun does not shine at night, but people still need light. Therefore, we want to “store” energy for later use.

New technologies and methods of managing the charging and discharging of batteries enable us to collect and store energy from various sources and release it in such a manner that we achieve the lowest possible energy loss and increase the beneficial effects and efficiency of the entire system.

For example, the use of energy from photovoltaic systems has proven to be problematic in recent years. A large generation capacity of solar power plants was installed and the distribution grid was not able to deal with fluctuations cause by intense sunlight, which in turn caused instability. It is therefore necessary to connect all processes of generating electricity from renewable sources and make it possible to use accumulated surplus energy at a later time.

The subject of the university team research is a device for storing electricity and, conversely, using at another time. This is a necessary part of the project, which is focused on obtaining energy from renewable and non-traditional sources, because energy thus acquired is not always available when people need it. Therefore, they developed a new transformer for the energy-accumulation system. In practice, it functions as a sort of bank in which energy can be deposited in the case of surplus production and then withdrawn in the event of an outage or sudden increase in consumption.

An advantage of this system is that it is not intended only for cities and villages, but can also be used as a backup energy source for industrial enterprises and as a source of energy in developing countries or in outlying and inaccessible areas where alternative sources, such as wind and solar, are used for generating energy.

Alternative sources of energy, such as water, sunlight and wind, among others, have enormous potential. However, production of energy from these sources causes instability in the distribution grid. Therefore, our objective is to connect all processes of generating energy from renewable sources and to store surplus energy for later use. They are working to ensure that we all will not notice any fluctuations.

ENET Centre, VŠB – Technical University of Ostrava in cooperation with Faculty of Electrical Engineering and Computer Science.

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

deRadon – “Cleaner wells guaranteed”

You have surely heard of radon, possibly during chemistry class at school or perhaps in connection with the radon risk. The danger of radon ensues from the occurrence of this radioactive gas in bedrock, from which it is absorbed by water, and the subsequent risk of its release and inhalation. The danger of radon consists in the fact that, due to its ionisation capability, it is able to damage the structure of DNA and cause uncontrollable cell reproduction. Waterworks and water-treatment plants can deal with radon. But radon can be found in the water that fills thousands of private wells. This radon escapes from the water and poses a threat to people who come into direct contact with this dangerous gas when, for example, drawing water from a faucet, but even more so when showering.

In order to remove radon from water, the university team developed the deRadon system, which effectively serves the intended purpose. deRadon comprises a device that is only somewhat larger than an ordinary water-heater and works on the following principle: air is forced by a compressor into approximately twelve tubes, each of which contains hundreds of thin, hollow fibres. The fibre wall is perforated with openings ranging in size from 10 to 100 nanometres. Drawn water flows around the tubes. Whereas droplets of water do not penetrate the interior of the fibres, radon fumes do and are then carried by the air current harmlessly into the outside atmosphere. The whole process is modelled on the properties of Gore-Tex fabric – drops of water do not penetrate the interior because of the material’s outstanding property called surface tension, though steam and gas pass through it to the outside.

The deRadon device is patented as a utility model and is intended for all owners of water resources whose wells are located in places with heightened occurrence of radon. Currently, deRadon is used in households with separate water sources dug out of ore or granite bedrock, where there is a heightened risk of radon, such as in the Jeseníky, Beskydy and Vysočina areas.

Faculty of Safety Engineering, VŠB – Technical University of Ostrava. The instrument is distributed by company Vodní zdroje Chrudim, s.r.o.

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Ecological heating

When burning solid fuels in small furnaces, the creation of pollutants always occurs. There are roughly four basic parameters that fundamentally affect the amount and character of these pollutants. This refers to depending to the type of combustion device, type of fuel, quality of operation and maintenance and the actual installation of the heating equipment itself. In other words, it is important what we heat in, what we heat with, where and how we heat and how the heater is maintained. Each of these factors significantly affects the quality of the combustion process, the efficiency of the combustion device and thus the consumption of fuel. If one of these parameters is deficient, then the overall result is bad. It is thus not enough to merely replace an old furnace with a new one and think that everything will be fine.

When heating with solid fuels, households produce approximately one-third of all dust released into the atmosphere in the Czech Republic. In order to improve this situation, the university team is working mainly on the development of new combustion devices as well as on the modernisation of old ones. They are monitoring the parameters of utilised fuels and examining the possibility of producing new types, such as mixed briquettes, pellets, etc.

The resulting emissions of harmful materials from furnaces are very dissimilar because product badges state ideal values that are often unachievable in real-world operation. They therefore pose the question: What does this have in common with heating in everyday life? They are thus wagering not on the parameters achieved during certification, but rather on the common sense of users. They created the SMOKEMAN character, who does not like smoke and shows the general public how to heat correctly and how to simply measure and, mainly, to improve the efficiency of furnaces. Much thus depends on us – a furnace is only a machine.

The educational show “Smokeman Intervenes” is intended for both young and old audiences. Children learn through comic books, board games and colouring books, while older people can experience at first hand how low-quality fuel and waste significantly influence the production of smoke.

They believe that patiently conveyed information will eventually result in beneficial habits of users. They hope that burning waste in a furnace will become taboo for the younger generation just as drying firewood is an absolute matter of course.

Energy Research Centre, VŠB – Technical University of Ostrava

http://vec.vsb.cz/smokeman

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Clean mining technology

To produce electrical or thermal energy we need ever-increasing quantities of source materials. They include fossil fuels, which are all types of coal, natural gas, uranium, and petroleum. We cannot influence the total global reserves. What we can influence, however, are new methods of their extraction, where we process source materials efficiently and make use of wastes to generate energy. At the same time, we want to leave the Earth as green as possible for those who will come after us. This is the central message of the project ICT, or Institute of Clean Technologies of the VŠB – Technical University of Ostrava, for extraction and use of energy source materials.

Their project tackles two primary tasks. First, they want to gather as much information as they can about the properties of the extracted source materials using modern instruments and use as many waste-less technologies as they can. In practice this means they seek new methods of using secondary source materials which they still call wastes. Then they have to find for them a market niche in different segments of industry.

The other task focuses on ecology and revitalization of mines after extraction. Extraction of raw materials is always an ecological intervention. The project aims to restore everything to the original state by soil remediation, reclamation and revitalization following mining activities. Simultaneously they endeavour to employ environmentally friendly technologies while mines and quarries are still in operation. And this works. A case in point is their collaboration with a producer of bituminous coal, OKD company, in introducing a new extraction method for coal reserves in protective pillars, which is also in use in Canada and the United States, and which prevents deformation and subsidence of the surface.

They also participate in many reclamation and remediation projects, such as those involving the spoil heaps Oskar and Václav, and they are currently addressing the issue of a spoil heap at the Heřmanice Mine in Ostrava. To get a better idea we will give you a concrete example from Heřmanice: Employing a new technology they want to use the residual content of coal in spoil heaps to generate electricity or another form of energy. They will then offer the re-sorted stone to the construction industry as another quality material.

Faculty of Mining and Geology, VŠB – Technical University of Ostrava, in association with specialists from Faculty of Mechanical Engineering, Faculty of Civil Engineering, Faculty of Safety Engineering, Faculty of Metallurgy and Materials Engineering, and Institute of Geonics of the Academy of Sciences of the Czech Republic.

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/kategorie/technicke-vychytavky/

Energy savings in industry

We can never fully use energy and losses will therefore always occur, whether we are converting energy from a chocolate bar into energy needed to run up a hill or electricity into heat. However, we can reduce losses.

Production in large industrial enterprises involves enormous consumption of energy. If we include heating, ventilation, lighting and air-conditioning, we arrive at huge numbers as well as substantial energy losses. However, the university team ise focusing not only on energy; they also have their sights set on conservation measures for energy-intensive operations such as hospitals, schools and other such institutions.

They are monitoring and dealing with, for example, energy consumption at Opava Hospital; they have prepared project documentation for the Lower Vítkovice Area Energy Centre; and they are cooperating with other firms both within and beyond Moravian-Silesian region. This involves solutions in the area of offtake of electricity, heating, cooling, ventilation and preparation of hot water. They always conduct an analysis of the current state of energy consumption and operational loading. They assess everything, perform simulations and design such solutions that will enable everything to function with maximum efficiency while reducing energy intensity. Thanks to a unique computer program specially developed for these projects and optimisation of all processes, they are able to significantly reduce an entire complex’s energy consumption.

The financial costs of energy and, at the same time, the burden on the environment are currently the most closely monitored aspects in the area of investments. Therefore, the resulting product of their solutions is not only lower consumption of electricity and the resulting lower costs, but also a fundamental reduction of impacts on the environment.

Energy Research Centre in cooperation with Faculty of Electrical Engineering and Computer Science, VŠB – Technical University of Ostrava

- Place

- VŠB - Technical University of Ostrava

- Website

- http://www.zlepsisitechniku.cz/technicke-vychytavky/ekologicky-pasovy-dopravnik/

Ecological conveyor belt

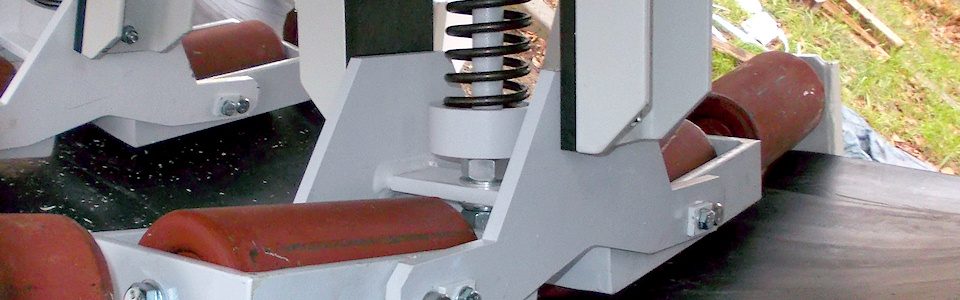

The conventional belt conveyors are reliable helpers in surface mines, thermal power plants, in the food industry, post offices, airports, but also in construction and reconstruction of buildings. They mostly transport material horizontally or with a slope of up to 18 degrees. The conveyor belt is made of rubber or plastic and the transported gravel, sand, grain or coal is easily held on it due to friction. Transport in larger inclinations is possible, but to overcome the force of gravity, it is necessary to modify the surface of the conveyor belt, for example by vulcanizing projections, grooving or retrofitting transverse ribs. This solution is not entirely complete and conceptual because the divided belt can hold less material. And there is still the problem of high dustiness during transportation…

The university team came up with the idea how to solve the problem. What about simply pushing the conveyed material to the conveyor belt? Imagine two horizontal conveyor belts one above the other, the bottom one is flat and the upper one has a shape of a convex trough. Each one moves independently of the other and the transported material is literally squeezed between them. It must be added that the design is not as simple as it might seem and requires many years of work and looking for the optimal solution. They have furnished the upper belt with pressure rollers to ensure the pressure of the material while preventing the raw material during transport from falling over the edges of the belt. This technology has many advantages. It is undemanding with respect to space, the conveyor belt can transport material from the ground floor to the upper floors, literally in the perpendicular direction. The conveyor transports more material at the same time, while the material is protected from the weather. Belts without transverse ribs are easier to clean, they are utilized more economically and they produce less dust, which has a positive impact on the environment. There are many good reasons why the technology of a double belt conveyor and roller mills was patented and why it is also protected by a utility model.

This device was developed by the team lead by Leopold Hrabovský from the Faculty of Mechanical Engineering, VŠB-TUO in cooperation with the company SE-MI TECHNOLOGY, a.s. within the project TAČR (Technology Agency of the Czech Republic) Alfa